WMV Specialized Lines

WMV Specialized Lines

All WMV Systems are designed to prevent part mixing. Process control, tracking parts, data collection, and the archiving of data is necessary when processing critical parts. All WMV lines are equipped with an operator computerized interface that is easily monitored, highly flexible, and provides real time graphics.

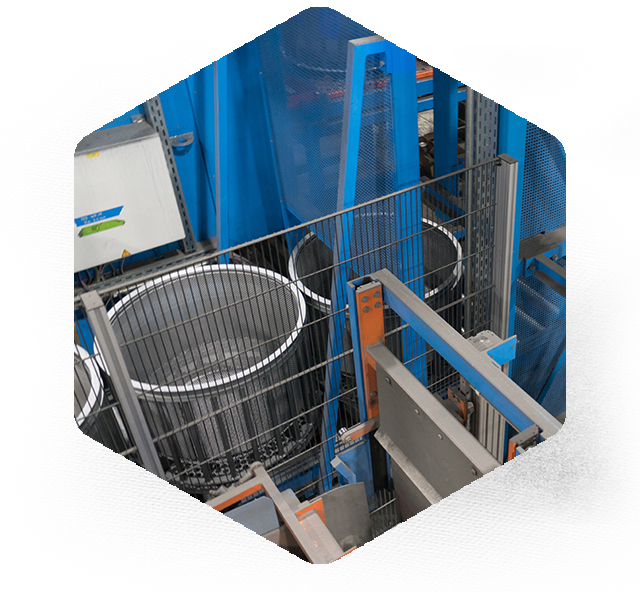

Gentle material handling and the movement of bulk product to and from various processes allows WMV to provide system solutions to our customers.

Gentle material handling and the movement of bulk product to and from various processes allows WMV to provide system solutions to our customers.

Coating Line

This State-of-the-Art line is unlike any other in the United States. Our Coating Line provides an Alkaline Wash, Shot Blast and Basecoats all in one process.

Alkaline Wash

Alkaline Wash

Ability to Apply a Variety of Basecoats

Ability to Apply a Variety of Basecoats

Shot Blast

Shot Blast

Soft-Handling Technique

Soft-Handling Technique

o Reduced Drop Distances: Minimizes thread damage

o Process Minimizes chance of contamination

Part Cleaning Line

Gentle material handling and the movement of bulk product to and from various processes allows WMV to provide system solutions to our customers.

o Tilt/Tumble: Reduces head-fill and thread-fill

o Reduced Drop Distances: Minimizes thread damage

o Process Minimizes chance of contamination

Tilt Capability Line