About Us

Michigan Metal Coatings Company Mission Statement

We are dedicated to the continued progression of our speed, quality, and innovations which are essential to remain a Proud Leader in the Metal Finishing Industry.

COMPANY PROFILE:

MMC is dedicated to the continued progression of our Speed, Quality, and Innovations which are essential to remain a Proud Leader in the Metal Finishing Industry.

MMC is an ISO 9001:2015 and A2LA code accredited applicator of the Geomet®, Doerken® and Atotech coating systems. Michigan Metal Coatings (MMC) is comprised of two facilities, totaling 170,000 ft.² and operated by 152 dedicated employees. A devotion to producing a quality product for each and every customer has helped to establish MMC as an innovator in the coating industry.

ACCREDITED LABORATORY:

MMC’s laboratory is both ISO 9001:2015 and A2LA code accredited. State-of-the-Art testing equipment enables MMC to conduct a variety of OEM required tests (Salt Spray Testing, CCT, Torque Tension, K-Factor Testing, Coating Weight & Thickness, Adhesion, etc.).

BULK DIP-SPIN TECHNOLOGY:

MMC’s Plant 1 Facility consists of six State-of-the-Art Coating Lines and one Part Cleaning Line. This is also where the majority of necessary testing is conducted, FREE of charge, by MMC’s accredited laboratory. All processing lines are specifically designed for their soft-handling features throughout the entirety of the coating process. This helps to greatly reduce the risk of thread-damage and/or marring that is common with Bulk Dip-Spin processing.

A sophisticated computer system is located on both ends of each line, making them fully-automated. This complex database ensures lot integrity and traceability every time your part(s) are processed.

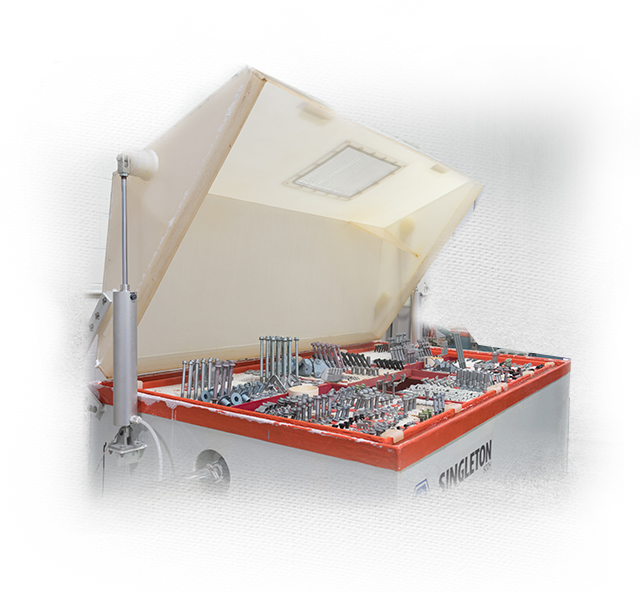

DDS RACK SYSTEM:

MMC’s DDS Rack System is the largest in the world, and it’s unique because the system is composed of an All-in-one-Process. Once parts are racked by a trained MMC Rack Operator they are washed, rinsed, dried, shot-blasted, base-coated, and top-coated if necessary. Once going through the All-in-one-Process, the parts exit the system as a finished product. Parts are then carefully taken off the rack and packaged to the customer’s specific requirements. The design of the DDS Rack System is the ultimate in soft-handling; parts are only touched twice (by hand) during the coating process. Thus, ensuring there is NO thread damage, thread fill, or part-on-part marring during processing. Due to its size and sophistication, the DDS Rack System is able to process bolts and U-Bolts in a variety of sizes. MMC processes parts from M6 to M36 in diameter and up to 750mm in length.

The DDS in “DDS Rack System” stands for Dip, Drain, and Spin. Unlike most other Rack Systems in North America, this system does not use a spray application for the coating process. Instead, parts are submerged in coating and slowly rotated which gives MMC the ability to process parts with complicated geometrics.

The act of rotating while parts are submerged ensures that regardless of the intricate design of a part, the entirety of the surface area is covered with coating. Parts are then removed from the coating and spun at high speed to achieve optimal coating thickness and weight on each and every part.

A strong leadership team dedicated to your success

Modern and efficient equipment to assure quality and speed

A fast turnover rate of only 4.2 days over the past four years

Attention to quality and detail that will exceed your expectations

Our Zinc Flake Coating History

Michigan Metal Coatings is an ISO 9001:2015 accredited applicator of the Geomet® , Doerken® and Atotech systems. Our company is comprised of 2 facilities, totaling 150,000 ft.² and operated by 152 dedicated employees.

1986

Michigan Metal Coatings is Established

2014

MMC is acquired by MC Systems, Inc.

2015

Installed RTO (Regenerative Thermal Oxidizer) Unit

Allows our company to provide a clean footprint for the environment.

2015

Installed the Nicchu J-Belt Blaster

2016

Double coating capacity on WMV Fully Automated Coating Line and WMV Fully Automated Part Cleaning Line

2017

Installed WMV Tilt Coater

2018

Transitioned to ISO 9001:2015

2019

Installed Sidasa Coating Line

2019

Installed WMV DDS Rack System

2023

Plant 1 Expansion

Expanding plant 1 and adding another WMV line to increase capacity and efficiency.

2023

Additional CCT Cabinet

Allows MMC to perform more CCT testing as a service to our customers.

2023

Additional SST Cabinet

Allows MMC to perform more SST testing for our customers.

MC Systems

MC Systems is a global company which employs 325 experienced and dedicated personnel. Located in Nagoya, Japan, MC Systems generates over $120,000,000 in annual revenue. MC Systems owns 9 companies totaling 11 facilities that incorporate 40 various state-of-the-art coating line technologies.

Accredited Laboratory

Michigan Metal Coatings Company is ISO 9001:2015 Certified

Michigan Metal Coatings Company is A2LA Accredited